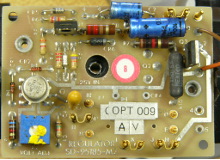

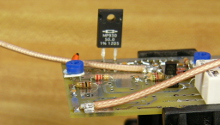

Régulateurs (2×)

Photo #

Regulators (2×)

Save mica insulator and plastic insulator for later re-install.

Test for regulation, with and without load (≈ 1A).

Correct any high-frequency oscillation on DC output (faulty capacitors, C2 or C3).

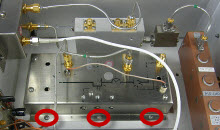

Mélangeur-abaisseur (RX)

Photo #

Position Down-Converter (RX)

Drill and tap, three places.

Noyaux d'accord (Oscillateur Local)

Photo #

LO tuning slugs ( 3× )

Solder extension to slugs.

Shims are used on the jig to center the extension on the end of the slug.

A blow torch is used to heat the material.

First, deposit a dab of solder on the end of the slug.

Slug must be kept clean and round so it rotates precisely within the resonator cavity.

Avoid heavy filing which may alter the uniformity of the slug.

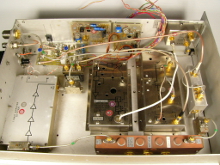

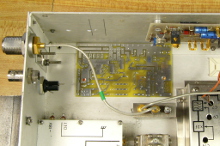

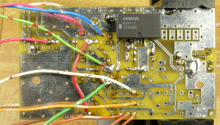

Montage des régulateurs et du diviseur

Photo #

Mount regulators and splitter

Be sure to use mica insulator, plastic insulator and heat-transfer compound on final assembly.

Panneau frontal

Photo #

Prepare front panel

- Power switch (12 VDC).

- Light Emitting Diodes:

- Power ON.

- TX.

- RF Out.

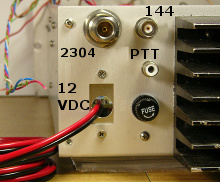

Panneau arrière

Photo #

Prepare back panel

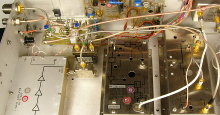

Trous de fixation de la plaquette

Photo #

Determine hole locations for board

Do before assembly, because one relay is fitted under board.

Réutilisation du coaxial le plus long

Photo #

Cut longest coaxial in 2 parts

- 144 MHz <-> Transceiver terminal, TC board.

- RX terminal, TC board <-> Down-Converter.

Cut carefully so both sections can be effectively re-used.

Plaquette d'interface DEMI

Photo #

Assemble DEMI interface board

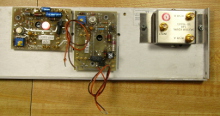

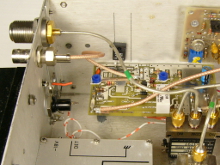

Mise en place de la plaquette

Photo #

Mount interface on stand-offs

Metallic stand-offs ensure ground connection.

Attach dummy load to side panel. Use heat-transfer compound.

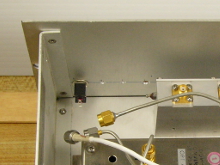

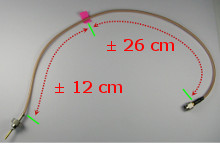

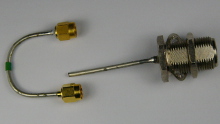

Lien semi-rigide en forme de "U"

Photo #

Photo #

Prepare short U-shaped coaxial jumper

Cut one of the lines formerly attached to the back panel. Solder SMA connector.

Used between PA and T/R relay.

Be sure to insert small Teflon® spacer before soldering centre pin.

Raccordements RF

Photo #